-

kowiri tira wai totohu raina production

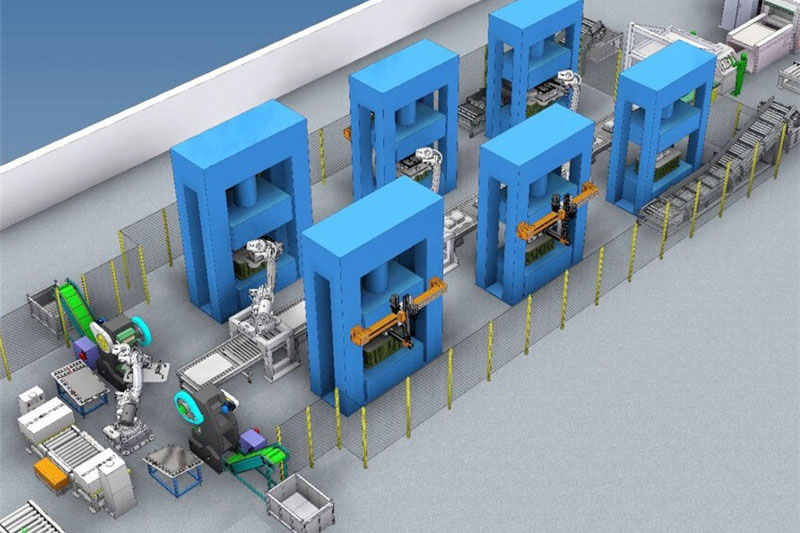

Ko te raina hanga totohu wai kowiri tira he raina whakangao aunoa e uru ana ki nga tikanga penei i te wetewete i te kowiri tira, te tapahi, me te hiri ki te hanga i nga totohu. Ka whakamahia e tenei raina whakangao nga miihini hei whakakapi i nga mahi a-ringa, ka taea te whakaoti aunoa i nga mahi totohu.

E rua nga waahanga matua o te raina hanga totohu wai kowiri tira: ko te waahanga whakawhiwhi rauemi me te waahanga tapatapahi. Ko enei waahanga e rua e honoa ana e te waahanga whakawhiti logistics, e pai ai te kawe i nga taonga i waenga i a raatau. Kei roto i te waahanga whakawhiwhi rawa nga taputapu penei i te weriweri porowhita, laminators kiriata, papatahi, kaitapahi, me nga taara. Kei roto i te waahanga whakawhiti raupaparorohiko nga kaata whakawhiti, nga raina whakahiato taonga, me nga raina rokiroki papapu kau. E wha nga tukanga o te wae pane kuini: te tapahi koki, te toronga tuatahi, te toronga tuarua, te kuti taha, me te whakamahi i nga perehi waipēhi me te aunoatanga karetao.

Ko te kaha whakaputa o tenei raina he 2 nga waahanga ia meneti, me te whakaputanga a-tau mo te 230,000 nga waahanga.

-

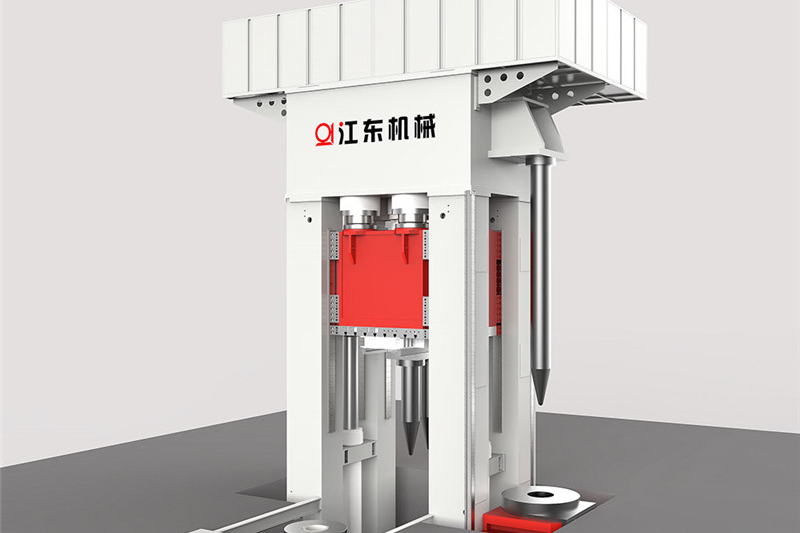

SMC/BMC/GMT/PCM Composite Molding Hydraulic Press

Hei whakarite i te mana tika i te wa o te mahi hangai, ka whakauruhia te perehi waipēhi ki te punaha whakahaere servo hydraulic matatau. Ko tenei punaha ka whakarei ake i te mana tuunga, te mana tere, te mana tere whakatuwhera moroiti, me te tika o te tawhā pehanga. Ko te tika o te mana pehanga ka eke ki te ± 0.1MPa. Ko nga tawhā penei i te tuunga kiriata, te tere whakararo, te tere perehi i mua i te perehi, te tere whakatuwhera moroiti, te tere hokinga mai, me te auau ngohe ka taea te whakarite me te whakatika i roto i tetahi awhe i runga i te mata pa. Ko te punaha whakahaere he whakaora hiko, he iti te ngangau me te iti o te paanga waipēhi, e whakarato ana i te tino pumau.

Ki te whakatika i nga take hangarau penei i nga taumaha kore taurite na nga waahanga hangarite me nga rereketanga o te matotoru i roto i nga hua angiangi papatahi, ki te whakatutuki ranei i nga whakaritenga o te tukanga penei i te whakakikorua i roto i te pokepokea me te whakarara whakarara, ka taea te whakauru i te perehi waipēhi me te taputapu whakaōrite e wha-kokonga. Ka whakamahia e tenei taputapu nga pukoro whakanekehanga teitei me nga reera servo whakautu tere-tere hei whakahaere i te mahi whakatikatika tukutahi o nga kaiwhakatere e wha-rango. Ka taea e ia te tino tika o te taumata wha-kokonga ki te 0.05mm i runga i te teepu katoa.

-

LFT-D muka roa whakaū i te kōpeketanga thermoplastic kōpeketanga tika niao raina production

Ko te LFT-D muka roa kua whakakahahia te whakamaarama whakamaarama whakamaarama tika mo te raina hanga hangai he otinga matawhānui mo te hanga rauemi hiato-kounga teitei. Kei roto i tenei raina whakaputa he punaha arataki miro muka karaihe, he miihini whakahiato kirihou muka karaihe mahanga, he kaikawe whakamahana poraka, he punaha whakahaere rauemi robotic, he perehi hiko tere, me te wae whakahaere.

Ko te tukanga whakaputa ka timata ma te whangai tonu i te muka karaihe ki roto i te extruder, ka tapahia, ka tukuna ki te ahua pellet. Ka whakawerahia nga pire, ka tere te hanga ki te ahua e hiahiatia ana ma te whakamahi i te punaha whakahaere taonga karetao me te perehi waipēhi tere. Ma te kaha o te whakaputanga a-tau o te 300,000 ki te 400,000 nga whiu, ko tenei raina whakaputa ka tino whai hua.

-

Ko nga taputapu Whakawhiti Resin Whakawhitinga Whakawhiti (HP-RTM) nga taputapu Carbon Fiber

Ko te taputapu Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM) he otinga tapahi i hangaia i roto i te whare mo te hanga i nga waahanga waro-kounga teitei. Kei roto i tenei raina whakangao matawhānui nga punaha whakahiato, he perehi motuhake HP-RTM, he punaha werohanga kapia teitei HP-RTM, karetao, he pokapū whakahaere raina whakaputa, me tetahi pokapu miihini whiriwhiri. Ko te punaha werohanga kapia teitei HP-RTM kei roto he punaha ine, punaha korehau, punaha whakahaere pāmahana, me te punaha kawe me te rokiroki rawa. Ka whakamahia he pehanga teitei, te tikanga werohanga tauhohenga me nga rauemi e toru-waahanga. Ko te perehi motuhake kei te punaha whakataurite e wha nga kokonga, e whakaatu ana i te tika o te whakataurite o te 0.05mm. Kei roto hoki i nga kaha moroiti-whakatuwhera, e tuku ana mo nga huringa whakaputa tere o te 3-5 meneti. Ma tenei taputapu ka taea te hanga puranga me te tukatuka ngawari o nga waahanga muka waro.

-

Tangohanga whakarewa/mate wera te hanga perehi waipēhi

Ko te Metal extrusion/hot die forging hydraulic press he hangarau hangahanga matatau mo te kounga teitei, te pai, me te iti o te kai o nga waahanga whakarewa me te iti, te kore ranei o nga maramara tapahi. Kua nui te tono i roto i nga momo umanga whakangao penei i te miihini, miihini, umanga marama, aerospace, parepare me nga taputapu hiko.

Ko te miihini whakarewa / wera wera mo te whakamaarama i te miihini hiko he mea tino hangaia mo te tangohanga makariri, te whakamahana mahana, te whakamahana mahana, me nga tukanga hangahanga mate wera, me te whakaoti tika o nga waahanga whakarewa.

-

Titanium alloy superplastic hanga press waipēhi

Ko te Superplastic Forming Hydraulic press he mihini motuhake i hangaia mo te hanga kupenga tata o nga waahanga uaua i hangaia mai i nga rauemi uaua-ki-te-ahua me nga awhe pāmahana deformation kuiti me te aukati deformation teitei. Ka kitea he tono whanui i roto i nga umanga penei i te aerospace, rererangi, hoia, parepare, me te tereina tereina.

Ko tenei miihini hydraulic e whakamahi ana i te superplasticity o nga rauemi, penei i te titanium alloys, te konumohe konumohe, te konupora konupora, me te wera teitei, ma te whakatika i te rahi o te witi o te rauemi mata ki te ahua superplastic. Ma te whakamahi i te pehanga ultra-iti me nga tere whakahaere, ka tutuki te perehi i te huringa superplastic o te rauemi. Ma tenei mahi hanga hurihuri ka taea te hanga i nga waahanga ma te whakamahi i nga taumahatanga iti rawa atu ka whakaritea ki nga tikanga hanga tikanga.

-

Te perehi waipēhi kore utu

Ko te Free Forging Hydraulic Press he miihini motuhake i hangaia mo nga mahi whaanui kore utu. Ka taea e ia te whakaoti i nga momo mahi hangai pera i te whakaroa, te whakapouri, te wero, te whakawhanui, te tuhi pae, te kopikopiko, te piko, te neke, me te tapahi mo te hanga i nga rakau, rakau, pereti, kōpae, mowhiti, me nga waahanga he mea hanga porohita me te tapawha. He mea taputapu ki nga taputapu awhina penei i te miihini miihini, nga punaha whakahaere rawa, nga teepu taonga hurihuri, nga paanui, me nga tikanga hiki, ka hono pai te perehi ki enei waahanga ki te whakaoti i te mahi hangai. Ka kitea nga tono whanui i roto i nga umanga penei i te aerospace me te rererangi, te hanga kaipuke, te whakaputa hiko, te mana karihi, te whakarewa, me te petrochemical.

-

Maama Alloy Liquid Die Forging / semisolid hanga Raina Whakaputa

Ko te Raina Whakangao Maamaa Maamaa Liquid Die Forging Production he hangarau hou e whakakotahi ana i nga painga o te maka me te hanga i nga tukanga ki te whakatutuki i te hanga ahua kupenga tata. He maha nga painga o tenei raina whakangao hou, tae atu ki te rere o te tukanga poto, te pai o te taiao, te iti o te whakapau kaha, te hanganga o te waahanga rite, me te mahi miihini teitei. Kei roto i te maha o te CNC wai mate mo te hanga perehi waipēhi, he konumohe wai konumohe ringihanga ine, he karetao, he punaha whakauru pahi. Ko te raina whakaputa e tohuhia ana e tona mana CNC, nga ahuatanga mohio, me te ngawari.

-

Pouaka Hau Poutū/Matā Whare Tuhia Raina Whakaputa

Ko te Raina Whakangao Tuhi Tuhi Tuhi Poutū Hau / Matā he mea hangaia mo te hanga i nga wahanga ahua kapu (te ahua o te oko) me te pito o raro matotoru, penei i nga momo ipu, ira hau, me nga whare matā. Ma tenei raina whakangao e taea ai e toru nga tikanga: te whakapataritari, te wero, me te tuhi. Kei roto ko nga taputapu penei i te miihini kai, te oumu whakamahana reo-auau, te whitiki kawe, te kai karetao / ringa miihini, te whakapataritari me te patu i te perehi waipēhi, te teepu kiriata rua-teihana, te whakawhiti karetao / ringa miihini, te tuhi perehi waipēhi, me te punaha whakawhiti rauemi.

-

Raina Whakaputa Tuhi Tuhi Whakapae Hau

Ko te raina hanga tuhi whakapae whakapae hau he mea hangaia mo te mahi totoro o nga puoto hau tino roa. Ka whakamahia e ia he tikanga hanga totoro whakapae, ko te waeine upoko raina, te karetao uta rawa, te perehi whakapae roa-whiu, te tikanga whakamuri rawa, me te wae hiku raina. He maha nga painga o tenei raina whakaputa penei i te ngawari o te mahi, te tere hanga, te whiu roa, me te taumata teitei o te automation.

-

Gantry Straightening Hydraulic Press for Plates

Ko ta tatou perehi waipēhi whakaraerae hiko he mea hanga motuhake mo te whakatikatika me te hanga i nga tikanga o nga pereti rino i roto i nga umanga penei i te aerospace, te hanga kaipuke, me te whakarewa. Kei roto i nga taputapu he upoko rango nekeneke, he anga mokowhiti waea, me te tepu mahi. Ma te kaha ki te mahi whakanekehanga whakapae i runga i te upoko rango me te anga gantry i te roa o te tepu mahi, ko ta maatau perehi waipēhi whakatikatika gantri e whakarite kia tika te whakatikatika pereti me te kore he matapo. Ko te rango matua o te perehi he taputapu ki te mahi moroiti-nekehanga whakararo, e taea ai te whakatika tika pereti. I tua atu, he mea hoahoa te tepu mahi me te maha o nga rango hiki i roto i te waahi pereti whai hua, e pai ai te whakauru i nga poraka whakatika i nga waahi motuhake me te awhina ano hoki ki te hiki i nga papa.

-

Gantry Straightening Hydraulic Press for Bar Stock

Ko ta matou perehi waipēhi whakakoi i te gantry aunoa he raina whakangao i hangaia hei whakatika tika me te whakatika i nga rakau pae whakarewa. Kei roto ko te waeine whakamaarama waipēhi pūkoro, he punaha whakahaere rapu (tae atu ki te rapunga totika o te taputapu mahi, te koki hurihanga o te koki mahi, te rapunga tawhiti o te waahi whakatika, me te rapunga whakanekehanga whakatikatika), he punaha whakahaere waipēhi, me te punaha whakahaere hiko. Ka taea e tenei perehi hydraulic maha ki te whakaaunoa i te mahi whakatikatika mo nga rakau papa whakarewa, kia pai ake te tika me te pai.